top of page

Search

Innovate with High-Toughness Copolymer Nylon 3D Printing for Medical and Industrial Customization.

The rise of flexible nylon 3D printing is revolutionizing how industries approach complex part design. High-toughness copolymer nylon, with breakthroughs such as 280% elongation at break (compared to 8-17% in standard PA12), now enables unprecedented durability in custom medical devices, including joint braces and prosthetics.

KINRAYTECH

How 5-Axis CNC Machining Transforms Aerospace and Medical Manufacturing

High-tolerance CNC machining and 5-Axis CNC Machining supplier.

KINRAYTECH

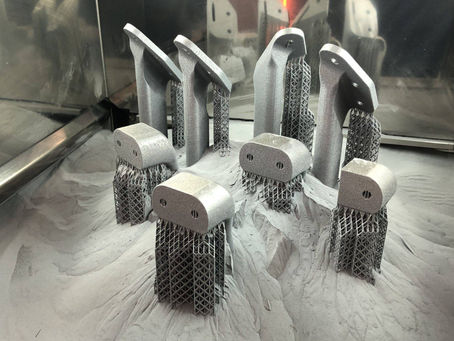

How long does it take to 3D metal print a wheel rim?

he time required to 3D metal print a wheel hub depends on several factors, including the hub's size, design complexity, printing technology, and equipment performance. Based on search results, the following are the main factors affecting printing time and some specific cases

KINRAYTECH

Forged Wheels and 3D Printed Wheels: Which Technology Dominates Future Automotive Performance?

Forged Wheels and 3D Printed Wheels: Which Technology Dominates Future Automotive Performance?

KINRAYTECH

Precision Machining Revolution: How Ergonomic Seat Components Enhance Automotive Comfort and Efficiency.

Kinraytech leverage automated deburring and punching systems (e.g., dual-axis CNC grinders) to mass-produce car seat armrests and brackets. OEM Ergonomic Seat Components.

KINRAYTECH

Unlock Precision Manufacturing for Lightweight & Multi-Material Components: Your Partner from Prototype to Production.

The worldwide's industrial design landscape is rapidly embracing lightweighting, multi-material integration, and intelligent assembly to meet evolving market demands.

KINRAYTECH

Why 3D Printed Saddles Are Revolutionizing Cycling Comfort in 2025

For cyclists battling sit bone pain or numbness, traditional foam saddles often fall short. Enter 3D-printed saddles—a fusion of precision engineering and biomechanical science that delivers unparalleled personalized comfort.

KINRAYTECH

The Metal Injection Molding (MIM) Revolution: Powering Next-Gen Robotics with Precision Engineering

Metal Injection Molding (MIM) technology now enables complex geometries once deemed impossible—delivering high-wear resistance, exceptional strength-to-weight ratios, and cost-effective mass production.

KINRAYTECH

AI-Driven Metal 3D Printing: Revolutionizing Aerospace and Medical Manufacturing

The fusion of AI-powered process optimization and metal 3D printing is transforming manufacturing from Germany to Singapore. With the metal AM market surging toward $1.5B by 2025,industries now leverage AI to cut errors by 40% and accelerate production.

KINRAYTECH

Precision Laser Cutting and Bending: Revolutionizing Sheet Metal Fabrication for Global Industries

precision laser cutting Sheet metal bending services have become indispensable for industries ranging from automotive to electronics.

KINRAYTECH

From Sketch to Scale: Kinraytech's Integrated industrial Manufacturing Solutions for Global Innovators(industrial prototyping to massive-production)

The Product Development Journey: Technologies & Transitions, From industrial protototyping to massive-production

Rapid prototyping to injection modeling full industrial sulution services.

KINRAYTECH

Why Vacuum Casting Prototype is the Smart Choice for Small-Batch Production

ooling costs for vacuum casting are 90% lower than metal molds, with per-part prices dropping significantly at volumes above 20 units.

KINRAYTECH

Why PEEK Gears are Revolutionizing High-Performance Industries?

From reducing aircraft emissions to enabling precision robotics, PEEK gears are the backbone of next-gen engineering. Partner with Kinraytech and we are always to harness our full potential to support your industrial projects.

KINRAYTECH

Quick-Response Foldable Lightweight Arm Shield (Carbon Fiber Composite)

Quick-Response Foldable Lightweight Arm Shield (Carbon Fiber Composite) manufactoure solution.

KINRAYTECH

Precision on a Micro Scale: How Custom Low-Volume Machining Solves Your Critical Manufacturing Challenges.

Custom Low-Volume Machining

KINRAYTECH

Problem Solved: "Tired of rods snapping in saltwater?" ,you need Carbon fishing rods manufacture solution.

Carbon fishing rods manufacture solution

KINRAYTECH

How to 3D print a model airplane

Application of industrial 3D printing technology in model aircraft,3D print model airplane 1、Design and modeling Acquire or design...

KINRAYTECH

The Characteristics of Nylon Materials

The feature of Nylon 3D print can cover the full range of industrial usage.

KINRAYTECH

Explore the Advantages of Precision Parts Processing for Your Manufacturing Requirements.

Precision Parts Processing- High-hardness titanium alloy precision wrench

KINRAYTECH

Industrial processes for prototyping and machining.

What are the industrial processes for prototyping and machining? These are some processes for industrial prototype and machining...

KINRAYTECH

bottom of page